High Precision Metal Surface Finishing - Electroplating

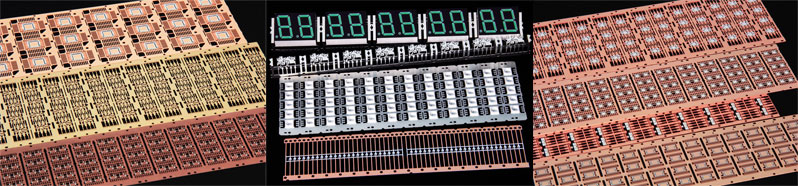

Reel To Reel Plating

High precision surface finishing or electroplating allows for better corrosion resistance, improved solderability and higher tarnish resistance on top of enhanced conductivity of components. As such, reel-to-reel precision plating is the preferred method for high volume components that require precise deposition of coating onto a designated area.

Our radius is designed for Reel to Reel and Barrel plating configurations. Amlex utilizes the latest quality testing and inspection equipments for both product and process analysis.

Amlex’s quality management system incorporates key quality documents which encompass, PFMEAS (Process & Design FMEA), DFMEA, control plans and flow charting. SPC analysis tools ( Cp, Cpk, Control charts ) and online parameter tracking are incorporated in key production processes.

Our excellence and experience in plating know-how and technology enable us to plate a very wide range of products and surface finishing options. Using our extensive knowledge in electroplating technology, our plating machines are designed and built in-house. We continuously conduct R&D to improve machine efficiency and capabilities especially in operational enhancements.

Barrel Plating

Amlex offers complete barrel plating services for gold, silver, palladium, nickel, tin and copper. Our customers bring us a wide variety of part with their own unique design & handling requirements which has driven us to be innovative in our electroplating techniques. Our barrel plating capability :

- Full Au / Ni / Pd Plating Processes.

- All our processes can cater to various types of raw material (Cu Alloys, Brass, Phosphor Bronze, Alloy 42, Mild Steel, etc.)

Plating Parts and Products

Amlex provides a wide array of surface metal finishing option to customers in the interconnect and semiconductor industries such as :

- Full area PPF (Pre-Plated Leadframes) using Nickel Palladium Gold finish to meet the application needs of green IC packaging. Our capability also includes Ultra Thin Plating configuration for this process.

- Spot plating capability via step and repeat process. Currently Amlex is providing spot plating for Silver and Gold process with tolerance of ± 3 mils. We are also embarking on new methods to save on gold usage.

- Selective Hard Gold and Solder Plating for connector terminals. We utilize techniques such as brush and depth control for connector terminal plating with 3D configuration.

- We also provide leadframe solder such as Pure Tin, Tin Copper (Taiko) and Tin Bismuth (Molex Malaysia). However due to certain physical property limitations where certain applications still require Tin Lead, Amlex has also made available this process as well.

Our other capabilities also include :

- Cu & Ni roughening process for the IC packaging industry to achieve MS level 1 on reliability.

- Electroless Nickel (EN) and Gold Plating using Barrel Plating machine. Our EN plating has been enhanced to the Hi Phosphorous version which is suitable for better sound solution application.

Our electroplating capabilities :

- Spot Au / Ag / Ni : ± 3 mils

- Full and Selective Ni / Pd / Au / Ag

- Full Ni / Pd / Au (Ni min 10µ” / Pd min 0.5µ” / bondable Au flash min 0.1µ” )

- Cu Roughening Process (CR1)

- All our processes can cater to various types of raw material (Cu Alloys, Brass, Phosphor Bronze, Alloy 42, Mild Steel, Stainless Steel, etc.)

Customers

Customers